Rhenium in the soil

Extraction of metals - what do you imagine? A mine in which workers and advanced machines struggle with rocks to wrench the precious ore. It turns out that there are a lot of different ways now. I'll tell you about the idea of two Bulgarian scientists who discovered a method of obtaining one of the rarest and most expensive metals on Earth – Rhenium.

One of the most expensive and rare metals can be derived from the soil in an eco-friendly way using lucerne.

In recent years, it became an especially important raw material, although it is one of the least common elements on Earth. It turns out that its characteristics are particularly useful to retain

its strength and flexibility at extreme high or low temperatures. It is getting more irreplaceable in the airline industry - almost all of the fins in the turbine of the aircraft engines are

made of rhenium-nickel alloy. The addition of nickel to rhenium makes it more resistant to high temperatures - and from the fact that the engine is operating in higher degrees, the fuel consumption

decreases. Rhenium can keep its characteristics to remain plastic, while the outside temperature is -50 C, and the battle in the engine is for each tenth of a degree.

10-15 years ago, this technology was used only in the defense industry - the U.S. "Phantom" and the Russian MiG. Now it is entering in the Civil Aviation and the participation of rhenium is among

the main reasons for the large "747" to spend 1.5 tons aviation fuel per hour against 6.5 tons for the older Tu-154. In the recent years, the same alloy enters in the turbine of the power plants –

the rare metal helps for higher performance. And it is irreplaceable for space technology. There is not a single nozzle of a rocket, which is produced from something else but by rhenium-wolfram–

alloy, two of the most hard-melting metals on Earth. The wolfram alone, wouldn't be able to finish the job because it is fragile in more severe conditions, whereas the addition of approximately 20%

rhenium makes it plastic and the nozzles withstand extreme loads. As the rocket takes off when it passes the atmosphere the temperature is 2500 C, and afterwards, it is in outer space where the

temperature is the freezing -273 C. As you probably have already understood, only the addition of rhenium can protect the nozzles at such huge amplitude. Therefore, 80% of the world's production is

for the needs of the air-space industry. The remaining 1/5th is for the production of unleaded motor gasoline, where the rhenium-platinum catalysts help for higher octane number in the distillation

of the oil. Rhenium fibers are also being implanted in camera flashes. Its last, but very important application is in the medicine. The metal is not toxic for humanbeings, and in the recent years

one of his isotope - rhenium-188, is used in radiotherapy for lung cancer.

The price of the gold

After all of the above, it is obvious that this metal could not be cheap and it is definitely not – after its mass production 5 years ago the price hit the astonoshing 12,000 dollars per kilogram.

In recent years, the crisis affected the airplane production, hence the price of the rhenium fell to the reasonable, but still impressive $ 4,500. The metal, however, is so rare that there are no

reserves big enough for it to be extracted on its own. That is why the big manufacturers are the countries producing copper or molybdenum, and along with those metals – the rhenium - Chile,

Kazakhstan, France, Germany, Netherlands, Russia, UK, USA and recently Poland. Just imagine how rare indeed - the richest rhenium mine in the world is in Stavanger, Norway - with ore approximately

3 kg of rhenium per tonne - or only 0.3% of the ore is precious metal. That is why the extraction is done along with the other two, quite common metals - molybdenum or copper

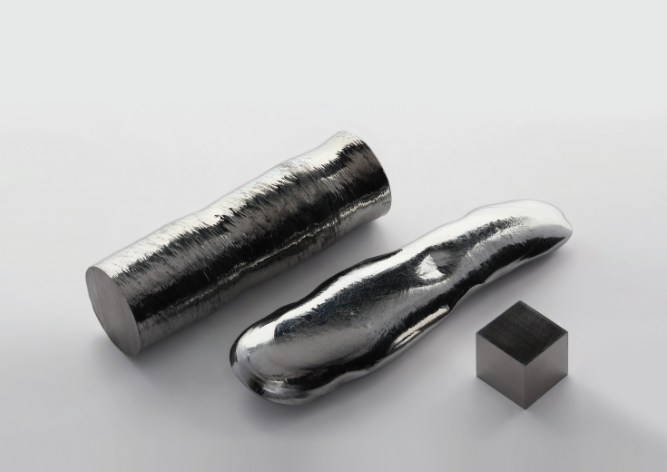

Rhenium metal

•It is among the metals with the highest temperature of melting - 3180 ° C – only the tungsten is ahead of it- with about 3422 ° C

•It is number 75 in the periodic system.

•It is named after the River Rein

•Re is its chemical symbol

•In 1914 Henry Mozli predicts its existing, even though Mendeleev suspected that it existed.

•In 1925 Walter Noddak, Ida Take and Otto Berg isolate it in Germany.

3rd page

and secondary the Rhenium is being "pulled". In the process called "roasting", rhenium forms a volatile oxide, which, if there are filters in the chimneys – is being caught by them. Unfortunately,

the yields are low, and not all factories are equipped with the necessary equipment - otherwise substance simply flies in the air. This method is 80% of the world production, the rest comes from

recycling. However, the extraction is insufficient for the increasingly rhenium-hungry industry. The annual production in 2012 is 45 tons, while the world needs are estimated at at least 60 tons.

Science so far has never been able to offer better solutions. Until after the problem was tackled by Prof. Ognyan Bozhkov and assistant Christina Tsvetkova from the Institute of General and

Inorganic Chemistry of the Academy of Sciences. After several years of studies, they are ready with a very promising technology, which is beneficial to the environment. Once the rhenium gets in the

roots of a plant, it starts to accumulate in the green zone - this applies both for terrestrial and aquatic species. Unlike many other elements, it is stored not in the roots or the stem but mainly

in the leaves - quite evenly. It is this quality that grabbed the attention of Bozhkov's team.

The plowed celery

Bulgarian scientists have targeted their attention to a very promising technology, called phyto-yield. It has developed over the last decade, so far mainly for nickel. The idea is that by planting

plants that can derive it from the soil, the specific metal can be extracted from waste waters and minerals with low content rather than mines. For that purpose, plants, which in scientific

language are called hyper accumulators, are being chosen - these are the species that can accumulate kg or more metal per ton of dry mass. In addition to yields this method is used for cleaning

contaminated soil – some plant species "soak" the toxic cadmium and lead from the soil and thus clean it. The first step of the Bulgarian team was to choose the exact spot where it is appropriate

to implement the method. They took samples of the soil and plants around various copper mines in the country, the highest content of rhenium samples were in the mine "Asarel" - the plants had an

average content of around 1400 times the average content in nature - still not enough for production, but enough for further studies. Then the researchers continued to trace how in the area around

the mine the precious metal ions are located. Scientists were able to trace its path. After the extraction of the copper the residual earth forms a heap aside. Rainwater and wastewater flow in a

small pond where the rhenium was 200 times more than the average. Its content was significantly more in the leaves of the oak growing near the water. But scientists have literally lost their words

after the results came out from the next sample - elder Bushes at the shore of the stream, which starts at a small lake - 44,000 times above average! It became clear that some of the rhenium from

the mine as a result of processing becomes water-soluble and accumulates in nearby plants in a sufficient amount so that the research can continue. The next step was to find a suitable plant

species that most strongly extracts the precious metal. Up to that moment in time no one has ever been looking specifically for plants which are hyper accumulators for that metal so the Bulgarians

began to work. They followed the literature for similar experiments; compared them with their studies and summarized what qualities should the plant that we're looking for ,have - it should

have a large amount of green mass and well developed root system, offering ACTE relatively fast, it should be easy to collect and not too pretentious for growing.

Mower

They paid attention to four types - buckwheat, salt bush, alfalfa and clover, and stated running laboratory tests. They mixed soil with enough high rhenium ions, planted the plants and waited. Once

the leaves began grow, they studied them. Two of them were the favorites - just seven days after that the new clover had already gained 35 kg rhenium per ton of dry mass. However, the winner was

the alfalfa. For weeks, the impressive 46 kg / t were in its leaves. The plant responded fully to the criteria of hyper accumulators. If the hay got burned, as it often did in the yield, the value

rises more than 6 times - almost 1/3 of the mass is the Rhenium! Impressive, especially when compared to highest content in the ore - 0.3% versus 30% in the ashes. The plant has already been

selected – they only had to check if it works in the soil like that of "Asarel." Scientists took samples from various locations. Early results were not particularly impressive - as the soil was

depleted, the Lucerne failed to develop fully - only small sprouts showed like in a Chinese restaurant. However, it still contained about 4.6 kg rhenium per ton ash. After a discussion with

the agronomists, Ass. Bozhkov and his team were convinced that with proper treatment and appropriate preparations, the alfalfa can develop fully. Another advantage is that once planted, it

can extract the metal in the next three years with minimal additional costs for cultivation. In Bulgaria it can be mowed 3 times per season. Moreover - the cultivation of alfalfa on depleted

soils recovers them. After harvest, there are two options. One is the hay to be burned and to extract the metal from the ash. It can then be used as fertilizer. If the substance is derived

directly from the hay, it can be used for feeding the animals without any risks, says Ass. Bozhkov . Even after several sowing, the Lucerne will not have low rhenium levels as the ongoing work of

the mine closes the loop, and the metal content of the soil does not change rapidly from the plant exhaustion. By the methodology of our scientists from the foliage white pollen is being

extracted, called ammonium perennial. That is how the metal is sold on the world market. And the end-user's work – the airlines is through relatively simple methodology to extract the silver metal.

The pollen is placed in a tube furnace that heats up to 800 degrees and purged with hydrogen, as the result is metallic rhenium, ready to become airline fins. After all the research, it is clear

that there is a green technology through which we can obtain the rhenium if we use the "help" of the Lucerne or other plant. And the environmental advantages are much more. On one hand, this is the

first proposal for clean production - all previous versions were not ecological in one way or another. On the other hand, the soil is not harmed but cultivated.

Harvest Time

The next step, the team prepares is to begin experiments in the field – an area is being surrounded where they found the highest content of rhenium and began a detailed sowing. After many

exhortations, scientists recently met with the management of the mine and were given green light for field studies.

By the teams calculations, after the incineration of 1 acre alfalfa the scientists expected to receive 159 kg of ash. At current prices, which tend to increase, the profit would begin at the price

of 3400 dollars per acre. Anyway, chemists believe that the planted technology has a great and undiscovered potential and it could be used in other places too - researches will continue in Pirdop.

The chimneys there were operating without effective filters for many years - the results, in the air went out not only our rhenium, but the harmful sulfur oxide and arsenic as well. With phyto

extraction is possible nearby soils can be purified and in addition - rhenium to be added. There are opportunities in other places around the world - scientists have set their eyes on other major

copper mines which meet the basic requirements - for example, in Arizona city of Tucson and the Chilean Pacific coast.

Prof. Bozhkov and his team did not fear that their method could be plagiarized – because of the fact that metal was long unknown to us, there are only a few team who know metal well enough.

Furthermore Bulgarians have a unique methodology that allows them to quickly recognize the content of rhenium, unmatched worldwide. The method seems pretty simple and easy, but there are also

specific difficulties. The only thing we can do is wish luck to prof. Bozhkov and his team in the next "harvesting" of the Rhenium.

An island in the Rhodopes

Touch the remains of a Mastodon for good luck and leave the rest to the cheerful people of Rakitovo view more »

After the hippopotamus

Besides the lion, shells, parrots and water lilies were also amongst the symbols of the Bulgarian rulers view more »

Supreme

Maya Karkalicheva traveled 15,000 kilometers in the U.S. before she fell in love with the beauty

of the Bulgarian mountains view more »